Making your own bullets can be great fun, and opens up a world of new opportunities for both experienced shooters and beginners alike. With the range of powders, casings, and coatings available today, with a bit of experience, you can make rounds that are perfectly suited to the type of shooting you do. And who knows, once your friends see the deadly accuracy and huge stopping power of the rounds you make, they may even want to buy some. Today, we’re going to take a look at some of my favorite reloading press options

These machines automate the ammunition manufacturing process, meaning that you can produce reliable and safe rounds more easily and much faster.

First, though, let’s take a look at why you should consider making your own ammunition, and what you need to start.

Table Of Contents

- Why Make Your Own Ammunition?

- What is the Major Advantage of Reloading Your Own Ammo?

- Getting Started Reloading

- Don’t Hurt Yourself

- Types of Reloading Press

- Two Types of Reload Press: Single Stage and Progressive

- Choosing a Reloading Press

- 4 Best Reloading Press Options

- Best Single Stage Reloading Press

- Best High-Volume Reloading Press

- Main Advantages of a Progressive Press

- Best Reloading Press Final Thoughts

- Recommended Reading

Why Make Your Own Ammunition?

I’ve been making my own ammunition for quite a few years now, and still find it a hugely enjoyable process.

I have a few friends for who the process has become a little repetitive and boring, but for me the process of carefully preparing each round is a joy.

The task is actually quite relaxing, you get the feeling of being a real craftsman, a satisfying feeling of a job well done, and then the ultimate satisfaction of firing off a round that you have made yourself.

Beyond this, there are a few other reasons to start making your own ammo. It can save you money in the long term, of course, because buying raw casings and powder is cheaper than buying pre-prepared bullets.

What is the Major Advantage of Reloading Your Own Ammo?

The major advantage of making your own ammunition is actually in the level of customization you are able to achieve. If you are an experienced shooter, you probably already have a few favorite rounds, but are also aware of some of the limitations of each.

By making your own ammo, you are able to design rounds that perfectly fit your needs, and this in turn will improve your shooting performance.

Still not convinced?

I know, for a lot of people, taking the decision to start making their own ammo can be a scary one. After all, you are messing around with live explosives.

If you still have doubts, know that the only obstacle you face is one of education – people have been making their own rounds for centuries, without the benefits of the internet, so get online and educate yourself.

Getting Started Reloading

Once you’ve taken the decision to start making your own ammunition, you have a few more decisions to make.

First, you need to decide which calibre bullets you are going to produce, and then pick out the various components that make up each round.

Deciding on a Caliber to Reload

Deciding on a calibre is likely to be the easier choice, because you already have a gun that takes a particular calibre.

Whilst a lot of people recommend using home-made ammunition in an old, less expensive gun to start with, my advice is actually the opposite. Make ammunition for the gun that you have the most experience with, whether it be a 9mm or a .380.

Firing home-made rounds through a gun you have plenty of experience with means that you are able to feel the difference between your rounds and shop-bought bullets much more easily, and make adjustments as necessary.

Second, you’re going to need to choose the components for your bullets. If that sounds intimidating, it’s worth reminding yourself of how bullets actually work, and remembering that in essence, they are quite simple devices.

Each consists of essentially three components – the brass casing on the outside, the powder that goes inside this, and the actual bullet tip itself.

Picking the perfect combination of these parts will depend on a vast variety of factors, from what you are using your rounds for, what is available in your area, to simply the rounds that your gun prefers.

Once you’ve got a bit of experience making rounds, you will find your own favorite components. But even then, each part is relatively cheap if you buy in bulk, so it is easy to experiment with different types of each.

Whilst the major one-off expense of making your own ammunition is the reloading press, which I will come to below, also note that for each calibre of bullet you are going to make, you need a “die”.

What is a Reloading Die?

This is a small piece of metal that acts as a guide for putting all of the parts of the bullet together, and the range available is quite staggering.

Most reloading presses come with a set of dies, but again you might want to experiment to find the set of dies that works for you.

Don’t Hurt Yourself

Sounds easy, right? Well, if done correctly making your own rounds is pretty easy, and can be quite safe, but you need to know what you are doing.

You are working with live explosives, after all.

Most accidents with home-made bullets are caused by adding too little, or too much, powder. These defective bullets are called squibs, but don’t let the cutesy name fool you – they can be deadly.

What Happens if I Use Too Little Powder in Reload?

Add too little powder, and the bullet will not generate enough power to get the round out of your barrel. If you pull the trigger again, thinking the round has gone off, or (even worse) if you are firing on automatic, the next bullet will smash into the one stuck in the casing.

This is a great way to destroy a gun. Seriously, if this happens there is a good chance your gun will be dead. :(:(

What Happens if I Use Too Much Powder in Reload?

Adding too much powder is even worse. In this case, the bullet will explode within your gun, almost certainly causing significant damage, likely blowing your gun to pieces, and potentially costing you a hand.

I don’t mean to scare you by talking about this, of course. It’s just a friendly reminder that you need to pay attention to what you are doing.

My recommendation, if you are new to making your own rounds, would be to ask a professional, or an experienced friend, to take you through the process.

In addition, for your first bullets make sure you use a light powder, so that even if you overfill your casings slightly, you are not going to accidentally make a bomb.

Types of Reloading Press

All those warnings out of the way, let’s take a look at the central part of any bullet manufacturing process – the reloading press.

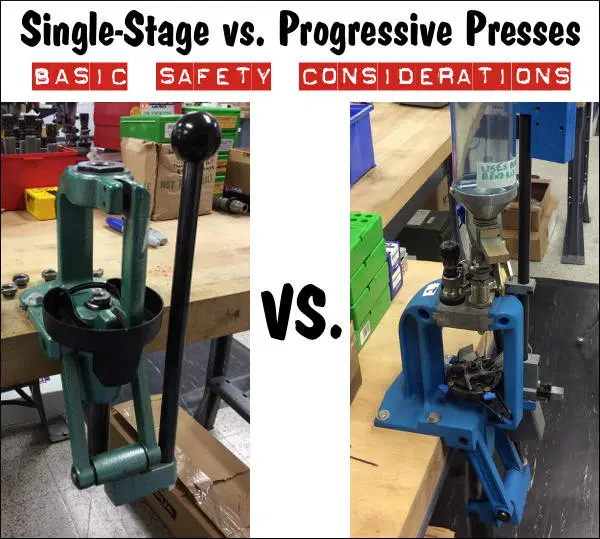

Two Types of Reload Press: Single Stage and Progressive

There are basically two types of reloading press: single-stage (or “turret”) presses, and progressive presses.

A turret press is the most basic type of press. It consists of a metal frame,in which your bullet is mounted.

When you pull the lever, a ram presses the primer and powder into the bullet casing, and pushes the whole assembly into a die.

With this type of press, each stage of making the bullet is done in sequence, and you make one bullet at a time.

A progressive press is a more complicated device. These presses automate more of the steps of making the bullet, so that every time you pull the lever the press can perform quite a number of individual actions.

They work like an assembly line, so that each time they move a bullet is moved onto the next stage of manufacture. They range from relatively simple devices, little more than a turret press, right up to machines that can do almost everything.

Progressive Reload Press Actions

With a progressive press, each time you pull the lever the machine can be performing a huge number of actions, like:

- Removing the primer from the used brass casing you inserted,

- “Resizing” the casing by reshaping it (within limits) so that it is the correct shape and size for the calibre you are loading,

- Placing a new primer into a casing,

- Dropping powder into a casing,

- “Belling” the casing so that a bullet can be placed into it,

- Pushing the bullet into the casing so that the finished round is at the correct overall length,

- Crimping the edges of the casing around the bullet, to hold the round together.

For this reason, these presses are a little harder to work with than simple turret presses. That said, watching an experienced user operate a progressive press, with dozens of parts working together, is a thing of beauty.

Choosing a Reloading Press

When it comes to choosing between a simple turret press and a progressive press, there is a standard recommendation – beginners should always get a turret press, because they are easy to work with. This is rubbish.

What Type of Reloading Press is Best for Beginners?

The received wisdom says that, for a beginner, turret presses are better because you can pay attention to each bullet as you make it.

With this type of press, people say, you are less likely to forget a key step, and each bullet you make will be a finely-crafted item, because you’ve spent a lot of time on it.

This might be true, of course, for the first dozen rounds you make. However, I hope that you are going to be super, extra careful with those rounds anyway. And trust me – using a turret press to make anything more than a hundred rounds is a real hassle.

This is not necessarily because the press itself is slow. It is more to do with having to fetch a new casing from the box, carefully position it in the press, load the powder by hand, then pulling the handle, then removing the bullet. Dropping casings quickly gets really tiresome.

4 Best Reloading Press Options

And so, all those musings out of the way, it’s time to choose your progressive press. As with everything to do with firearms, the best press for you will depend on your individual requirements, and your budget.

However, I’ll take you through a few options that are good choices for beginners, more experienced re-loaders, and finally the experts among you.

| Product Name | Where to Buy | |

|---|---|---|

| Hornady Lock-N-Load AP | |

| Dillon Precision 4 Stage Progressive Reloader Press | |

| Dillon Super 1050 Reloading Press |

Best Single Stage Reloading Press

If you are just getting started, and aren’t looking to load 1000s of rounds each session, then a single stage loading press will work. Once you realize the benefit of reloading your own ammo you will probably want to upgrade. That said, here is a great option to get started:

Hornady Lock-N-Load AP – Best Single Stage Reloading Press

This reloading press is great to start with because it can be expanded to add parts that make it more of a progressive reloading system. As a single stage, a very solid yet lightweight press. Includes a removable priming system. The lock and load system makes it easy tp lock and unlock the die.

Dillon Precision 4 Stage Progressive Reloader Press – Best Automatic Reloading Press

If this is your first foray into making your own ammunition, my advice would be to get a Dillon Precision 4 Stage Progressive Reloader Press. It’s a bit cheaper than the other presses below, but is a solid piece of machinery that also comes with a lifetime guarantee.

The speed achieved by this press, once you get used to it, rivals that of more expensive presses, and the relatively simple mechanisms used mean that you can easily see if something goes wrong.

In addition, it has a big advantage for those who are new to producing their own bullets – its compact size. It won’t take up your whole workbench, so you can play around without making a huge space investment.

That said, there are some drawbacks. This is limited in calibers it can load, and is only available in widely-used calibers. If you want to load wide range of rounds, look elsewhere, but in all other respects this is a respectable press to start on.

Best High-Volume Reloading Press

If you plan to make thousands of rounds a year, of course, it’s worth investing in a serious press. These can cost thousands of dollars, but you get a lot for your money. A press like the Dillon Super 1050 is capable of producing 1,000 rounds an hour, even on manual operation, and can form the basis of a truly professional reloading system.

Dillon Super 1050 Reloading Press

Beyond the extra functions that these top-end presses perform, they also incorporate features to make your ammo more reliable and safe. By automating almost every step in the bullet-making process, they take away a lot of the worry of preparing incorrectly-made cartridges.

And, of course, high-end presses like this are designed to work with automated systems, so you can easily add a powered mechanism to make your press even faster.

Automation

Once you are experienced at making your own bullets, the next natural step is to automate your press. By adding a powered drive to your press, you will not need to manually crank a handle, and this ultimately makes the press easier to use, if not necessarily faster.

There are plenty of automation devices available for almost every part of your press, from those that simply pull the handle for you, to those which automatically load new casings into your machine. The mid-range and high-end presses mentioned above are designed to work with this kind of mechanism.

Your options in terms of automation are quite diverse, from simple powered cranks to control sensors that incorporate touch-screen readouts and sensors to pick up any problems during reloading. For the Dillon 1050 recommended above, two of the most popular automation devices are the Mark VII and the Ammobot.

Main Advantages of a Progressive Press

The reasons to get a progressive press stem from the reasons you want to make your own ammunition in the first place. I’m going to bet that, if you are even considering making your own ammunition, you are already an experienced shooter who fires off hundreds of rounds a month.

If you want to make your own bullets, you want to make a few thousand a year.

Scale

For this reason, it makes sense to get the fastest type of press you can, right from the beginning. Whilst getting a turret press is a lot cheaper than even a basic progressive press, in the long run it will save you a lot of time.

And even if you don’t think you are going to be making thousands of rounds now, think about the future. Getting a decent reloading press will mean that, for many years to come, you are able to make exactly the type of ammunition you need.

Safety

That said, progressive presses do take some time to get used to. Each time you pull the lever, you are going to need to check each of the four or five bullets that are in the process of being made, and make sure that each action has been completed properly.

For a beginner, this can be quite a complex task, and it is for this reason that most people would recommend you start with a turret press.

I think, though, they are overlooking an obvious way around this problem – just because a progressive press will perform three, four, or five actions each time you pull the lever, you don’t actually have to have bullets loaded at each stage.

You can just as easily follow one bullet through each stage, and doing this is exactly like at … turret press. Except easier, and safer.

So you can use a progressive press like a turret press, but not the other way around. To my mind, this makes a progressive press the obvious choice.

Speed

As I said before, once you get some experience a progressive press is simply much faster than a turret press. A good progressive press, in the right hands, can produce 300-600 rounds an hour, in comparison to a mere 100 for a turret press.

Whilst carefully hand-crafting each bullet, spending a minute or more on each, might sound romantic at the beginning, once you are making a thousand rounds a year you will really come to appreciate the speed of a progressive press.

There is another huge advantage of progressive presses, and it comes when you need to change the caliber of bullet you are making. Each die you load into your press is good for a particular caliber, and if you change caliber you need to change the die.

Now. On a turret press, this is a hassle. You will need to partially disassemble the press, install the new die, and then make sure it is installed correctly.

A good progressive press, on the other hand, will allow you to have all your dies installed at once, and swap between the pretty easily. This means that after you install and adjust them, you will only need to check that they are still true and functioning correctly.

This makes loading different calibers in the same sitting much, much easier. It also reduces errors caused by incorrectly-installed dies, making your ammunition more reliable and safer.

Best Reloading Press Final Thoughts

Once you’ve armed yourself with a bit of knowledge, and have purchased a good reloading press, you are ready to start making your own ammunition. However, this is only the start of a long and enjoyable journey.

As your practise and skill at making ammunition increases, there are a range of workshop tools and accessories that are available to make your work quicker and more professional, and you will quickly find what works for you. I know guys, for instance, who swear by a particular brand and size of caliper, and who would not even consider changing.

And once you’ve made a few bullets, I guarantee that you want to experiment. There is a huge range of different casings, weights, and shapes available today, all of which can affect the accuracy and power of a round, and with your new reloading press you can try them all.

Happy experimenting!

Recommended Reading

Hearing Protection For Shooters

Best Shooting Chronograph Units

Shooting Protection For Competitive Shooters