The beauty of the AR-15 is how versatile it is. You can change your AR-15 from a long-range sniper rifle to a close-quarters carbine just by changing uppers and lowers. We will review 3 of the best AR 15 lower receivers for those on a budget.

Table Of Contents

Why is the AR 15 the Most Popular Recreational Rifles?

The AR-15 is one of the most popular recreational rifles for several reasons.

Number one: it is similar to those used by the United States military. Although the AR-15 does not have the fully automatic capabilities of the M-16 or the M-4, it looks close enough to the real deal to satisfy the desire for coolness among recreational shooters.

Number two: the AR-15 is extremely shooter-friendly. Recoil is very light when the firearm is chambered with 5.56×45 rounds. AR-15s are also very ergonomic compared to other rifles.

Number three: the AR-15 is extremely customizable, built with – as we’ll see in a minute -the same material used by the US Navy and Airforce for reinforcing modern warships.

The modular design of the rifle means you can swap out uppers and lowers within a few seconds.

First we will talk about AR 15 origins.

How the AR-15 Came to Be

The AR-15 was first designed by a man named Eugene Stoner. Stoner developed the rifle as a lightweight alternative to the AR-10 while working at Armalite during the 1950s.

The lighter bullet used by the AR-15 enabled infantrymen to carry an increased number of rounds without adding to the weight of their gear. The AR-15 is the civilian semi-automatic version of the select fire M-4 rifle.

The lower is the “body” of the firearm and is the only part that requires registration. You can have as many uppers as you wish without needing to fill out additional paperwork.

You can further customize the lower with aftermarket products to design the rifle according to your personal preferences and intended use.

But don’t get too carried away… There is a stigma (especially online) attached to those to load their rifles up with too much stuff.

These people are called “mall ninjas” and are accused of trying to be too “tacticool.”

Because the lower is where all the action takes place (no pun intended), it’s important that it be made well.

I hear your questions:

Why are some AR-15 lower receivers more expensive than others?

Why some AR 15 lowers are more expensive than others comes down to how they are made.

How AR 15 Lowers are Made?

Most lower receivers are made from aluminum. While there are other options such as steel, polymer, and titanium, this article will focus on the three different ways aluminum is made into the receiver for an AR-15.

Two types of aluminum alloys are used in making lowers: 6061-T6 and 7075-T6. What’s the difference between the two? The answer is strength and resistance to corrosion. The figures are as follows:

6061-T6 Aluminum

The AR-15 started as the M16, back in the 1960s. When its designer, Eugene Stoner, conceived of the M16, he planned for the receiver to be built with 6061-T6.

This was all well and good – 6061 aluminum was plentiful, being used to weld rivets on Navy tankers and as chases for various Army vehicles. Yet around 1968, the military switched from 6061-T6 to 7075-T6 aluminum.

The switch from reliable 6061 to a different form of aluminum was expensive at the time, but necessary. Many of the M16s used in the Vietnam War were starting to corrode after exposure to the elements of jungle warfare, and soldiers on the ground needed a solution.

Thus, Stoner recommended that the military switch to 7075 to fix the issue of corrosion (a common misconception is that it would make the receivers “stronger”, which was not necessarily true).

As evidenced by its widespread use in hangars and shipyards around the country, 6061-T6 aluminum is the superior option for welding and milling and resists corrosion under normal conditions.

6061-T6 AR 15 Lower Specs:

- Tensile strength: 45,000 psi

- Yield strength: 40,000 psi

- Shear strength: 31,000 psi

- Elongation: 17 percent

- Brinell hardness: 95

7071-T6 Aluminum

7071-T6 AR 15 Lower Specs:

- Tensile strength: 83,000 psi

- Yield strength: 73,000 psi

- Shear strength: 48, 000 psi

- Elongation: 11 percent

- Brinell hardness: 150

7071-T6 aluminum is nearly twice as strong as 6061-T6 aluminum. As a result, there will be a difference between the two in cost.

Most AR-15 lowers on the market today use 6061 because it’s easier to mold and quite hard. Further, most lightweight handguards for AR rifles are also made of 6061-T6.

6061 vs 7071 AR 15 lower – Does it matter?

So why does 6061 take a lot of flak for being not as strong if it is so commonly used? Most of the hate comes from armchair elitists who will say stronger is always better and to never use lesser materials. When it comes down to the wire, stronger aluminum can’t hurt, but 6061 works and has worked, for decades.

What does this mean for you?

Go ahead and buy that cool billet lower that is made of 6061 and be happy with it. Don’t worry about it breaking, despite what all the non-scientist elitists say. Just don’t take it to Vietnam.

When planning the build of your firearm, weigh the pros and cons of strength versus corrosion resistance to determine which type of metal you wish to use as your lower receiver.

If you cannot afford the more costly 7071-T6, 6061-T6 will be sufficient.

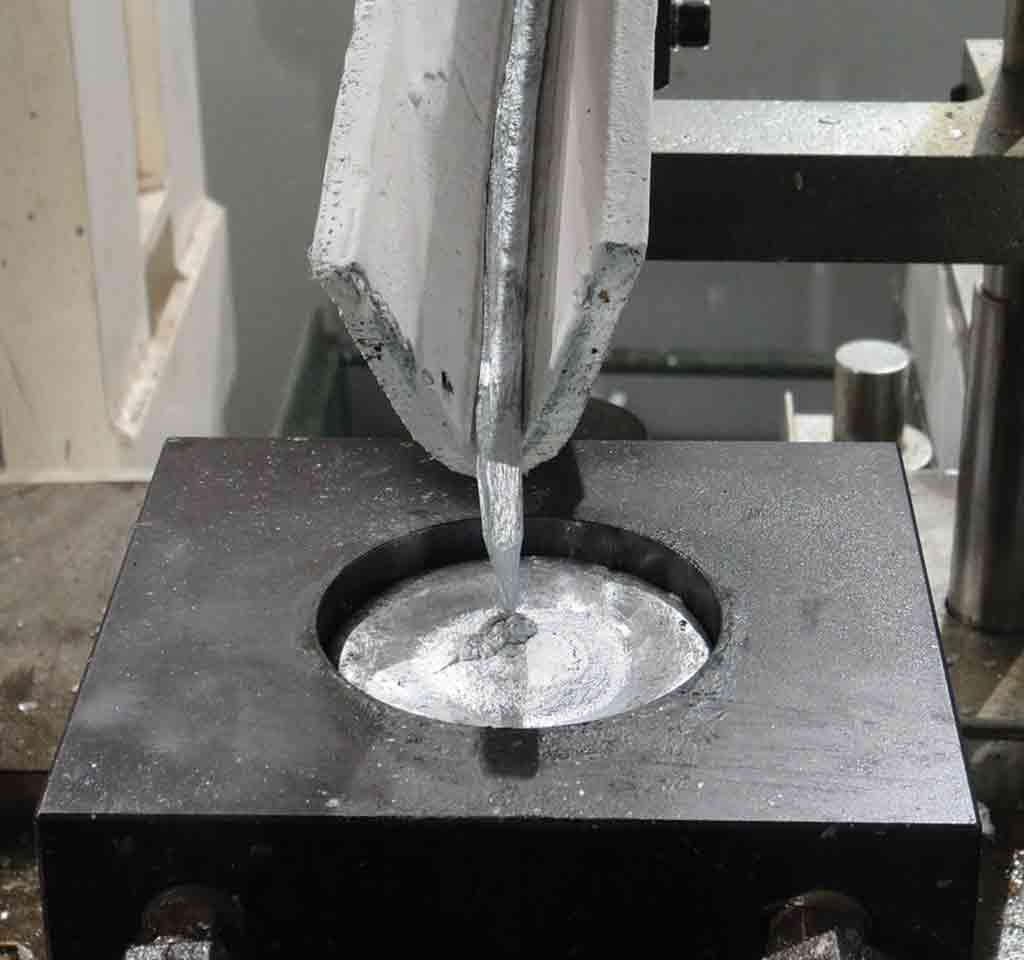

Cast Aluminum AR 15 Lowers

The casting process for aluminum is relatively basic. The molten aluminum is poured into a mold and allowed to cool. Once set, it is broken out of the mold, ready for the final machining process.

However, it is still strong enough to withstand the pressure of firearm operation without risk of malfunction or damage.

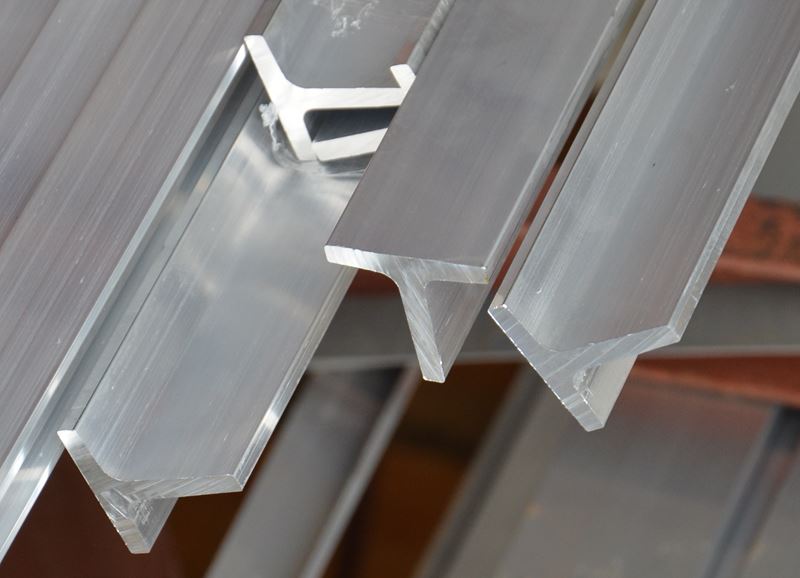

Billet Aluminum AR 15 Lowers

With the billet manufacturing method, the lower starts its life as a solid block of pure aluminum. Over the course of the manufacturing process, it is machined and milled on a series of equipment modules.

These lowers are also easier to customize than cast aluminum. Creative changes such as skull-shaped magazine wells and built-in trigger guards are simpler to create with raw metal.

Forged Aluminum

This type of aluminum is the strongest form and is most commonly used for lower receiver manufacturing. The forging process basically consists of taking aluminum and forcing it into the desired shape.

The final machining process finishes the lower receiver. The compression caused by the forging process increases the strength of the aluminum.

Which Type of AR 15 Lower Receiver Should You Choose?

We believe you should not choose a cast AR 15 lower receiver for the following reasons: 1) They are weak. 2) They are ugly.

Most websites will tell you that it is ultimately your decision and that you should consider the pros and cons carefully before making your decision. We at Gun News Daily think it’s helpful to include some examples of high-quality lowers and talk to you about them. Then you can make an informed decision about the lower you need.

I’ve never used a cast receiver in any of my builds and would never recommend one to a fellow shooter. All that said, here are the top picks we’ve come up with.

The Best AR 15 Lower Receivers on a Budget

| Product | Rating | Price | Where To Buy | |

|---|---|---|---|---|

| Anderson Manufacturing | 9.8 | $ | |

| Aero Precision | 9.6 | $$ | |

| 2A Arms Balios Lite | 9.3 | $$$ |

Anderson Manufacturing

We call this the Honda of lower receivers. Anderson lowers are inexpensive at $49 for stripped lowers and $120 for complete. They are made from forged 7071-T6 aluminum and are generally in stock.

I’ve used these lowers on countless builds and have never had any trouble with them. If this is your first time assembling a custom AR-15, I strongly suggest you choose this lower. If you scratch the metal during the assembly process, no big deal.

Don’t let the low price turn you away. These lowers are excellent as a basic lower for 90 percent of any build you design as a recreational shooter.

Aero Precision

Like Anderson Manufacturing, Aero Precision lowers are forged 7075-T6 aluminum but with a fancier logo. You can pair the lower with an Aero stripped upper receiver for a streamlined appearance. Aero Precision’s lowers are a little pricier at around $90 at the lowest.

2A Arms Balios Lite

The Balios Lite comes on its own as a lower for $292 or as an upper/lower set for $499. This lower is my current favorite and will be on the next build I design.

It is one of the more expensive lowers, but it makes up for the cost with the wide number of build options compatible with it.

This receiver is even lighter than the B.A.D lower at 6.5 ounces. Some of my favorite features of this lower receiver include the contoured front for an ergonomic grip, an angled magazine well for faster reloads, and the built-in trigger guard.

The reduced weight and the flared magazine will be perfect for the unique side-charger Go-Bag gun I intend to build with this lower.

The only drawback is its availability. The Balios Lite is difficult to find and is usually several weeks on back-order from the manufacturer.

Best AR 15 Lower Receivers – One Last Piece of Advice

Admittedly, these AR 15 lowers are only a sampling of those available. We selected these to give you a general idea of what high-quality AR 15 lowers on a budget look like. There are many other companies who manufacture and machine good lower receivers.

When you are evaluating the best AR 15 lower receivers for purchase, be sure to take into consideration the material, the manufacturing process and the manufacturer’s reputation. Once you’ve decided on the manufacturer you wish to go with, you can check and see if your local gun shop has what you’re looking for to save on shipping costs.

One good way to determine the quality of a company’s lowers is to take a look at their rifles.

If the AR is well-made from the get-go, the lower will be worth your time and money.

Recommended Reading

Best AR-15 Calibers And Cartridges

8 Responses

Ronald, you’ll probably never see this, but you need to do a lot more reading before you build a custom firearm.

For the record, any standard AR-15 lower will work with .300 Blackout. Or did you mean .300 Winchester Magnum? Because you didn’t specify WHICH “.300” cartridge you want to use. (Hint: 300 Win Mag will NOT work in a standard AR-15).

And also, yeah, it’s 7075-T6, NOT 7071. I thought it was a simple typo, but the author mages the same mistake over & over again, which tells me that that genuinely don’t realize the difference.

Case in point, my own credibility, and more importantly, the point I am trying to make would be better served if I had followed my own advice and done a little proof reading “on” my own writing. I hate when that happens.

Again, regards,

Duke

A bit of a credibility concern here. As a aerospace engineer, aluminum is a main stay of materials used in our products. To my knowledge, I have never run across on even heard of 7071 material. I believe any reference to 7071-T6 in the above article is an editing error and should read 7075-T6. From what I can tell based on my own knowledge, none of the information presented about the material properties are incorrect, the inability to adequately proof and edit the article tends to discredit the accuracy of the content.

That said, I am knowledgeable enough on the materials that they are not my concern in this article. I picked up the article to better understand the application of the materials to the product. I don’t disagree that 6061-T6 is an adequate strength material for a “standard” (definition open to interpretation) use AR style rifle.

I will continue to read your articles, but it would better serve your purpose switch off the auto-correct feature on you word processor and do a little pre-publication proof reading and editing.

Duke

lmao amen

Spike’s emblem is a spider. I’m sure you have seen it. But truly have you ever really seen it. I don’t think so and here’s why. How did emblem up straight up and down. What were the spiders pictures are now seen in reality and they are two horns. They are on the head with two eyes that go to the neck and then down to the body. There are two arms and two legs. Now look very closely at that depending on which illustration you get. But most of the times one of these sets of the arms and one set of the legs is not notice I said not attached to the body. I see a demonic figure. That’s not all also look at the last three numbers of their phone number and you will see 666. I was curious so I called him about it they immediately responded and said that they’re Christian organization. Then I thought to myself how many other Christian organizations advocate skulls , zombies ajd punishers. On YouTube there’s also a video it’s the new Jack lower and it’s of a skull lower receiver. It’s the video that says with Spike himself. That video shows him standing in front of a truck period on the who did that truck there’s words and they are written from right to left. It says soul stealer. Who is the soul stealer? Satan is that’s who. Can you see what I see now.

I’ll bet Troy has a piece of toast with Jesus on it.

Long time to reply, I just found this article. I’m a Christian and spike won’t get my money. Thank you.

Hi my name is ron. Im looking to build my first shotgun, and or rifle. But i am in need for an answer. Do they make a lower specifically for shotguns? Will a ar lower work for a .300?. Where might i find such a lower? Can i purchase from your site?